Exhausted Air Louver Roll Forming Machine Supplier in UAE

Basic Info

Model No.: BOSJ-S

Product Description

Model NO.: BOSJ-S Automatic Grade: Semi-Automatic Type: Rolling Machine Feature: Automation Warranty: 12 Months Forging Forming Method: Free Forging Trademark: BOSJ Control Type: CNC Drive: Electromagnetic Power Source: Hydraulic Pressure Advantage: Easy to Maintenance Certification: SGS, ISO9001, CE Customized: Customized Origin: Jiangsu 1, Forming process

De-coiler— Servo feeding— Gap and cut off mould— Forming ---collection table

2, Flow diagram

3, Equipment composing parts

Equipment is composed of de-coiler, feed system, gap and cut off, forming machine, collection table, electric control system, etc.

4, Technical parameter of equipment main parts

1, Auto-decoiler

A, Load capacity: 2 T

B, Inner diameter of coil: 490-510mm

Outer diameter≤ 1200mm

2. Servo feed and punching unfilled corner parts

A, Servo motor: Used Mitsubishi Servo motor, power: 1.0kw

B, Punching unfilled corner die: 4 pillars punching die

C, Material of punching die: Cr12. Quenching treatment

2, Feeding: Power 0.37kw

3, Forming machine

A, Forming frame

B, Material of forming mould: GCr15, quenching treatment: Rigidity: HRC56-62º

C, Motor: 7.5kw frequency conversion engine

4, Electric control: PLC system

Contact us if you need more details on Fire Damper Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Automatic Door Frame Roll Form Machine、Auto Msfd Frame roll forming machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

De-coiler— Servo feeding— Gap and cut off mould— Forming ---collection table

2, Flow diagram

3, Equipment composing parts

Equipment is composed of de-coiler, feed system, gap and cut off, forming machine, collection table, electric control system, etc.

4, Technical parameter of equipment main parts

1, Auto-decoiler

A, Load capacity: 2 T

B, Inner diameter of coil: 490-510mm

Outer diameter≤ 1200mm

2. Servo feed and punching unfilled corner parts

A, Servo motor: Used Mitsubishi Servo motor, power: 1.0kw

B, Punching unfilled corner die: 4 pillars punching die

C, Material of punching die: Cr12. Quenching treatment

2, Feeding: Power 0.37kw

3, Forming machine

A, Forming frame

B, Material of forming mould: GCr15, quenching treatment: Rigidity: HRC56-62º

C, Motor: 7.5kw frequency conversion engine

4, Electric control: PLC system

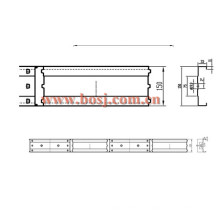

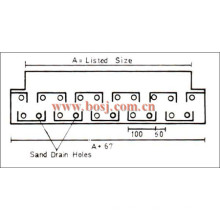

| NO. | Project | Unit | parameters | Remark | |

| 1 | Material | type | Mild steel Galvanized sheet | ||

| Strength of material sheet | Map | ≥350 | |||

| Thickness of material sheet | mm | 0.8~1.5 | |||

| 2 | Size of production | mm | Reference the picture | ||

| 3 | Production speed | m/min | 6~8 | ||

| 4 | Material of roller | GCr quenching treatment | |||

| 5 | Drive type | Gear box | |||

| 6 | Power | kw | About 34 | ||

| 7 | Electric control system | PLC variable frequency control | |||

| 8 | Dimensions(Length*width*height) | m | 28X4X3.9 | ||

Product Categories : Vane Damper Roll Forming Machine

Other Products

Hot Products

EPS Sandwich Panel Machine (AF-S1000)C Purlin Roll Forming Machine (AF-80-300)H Beam Welding Lineguard rail forming machineroll forming equipmentDump truckCovering Machinecold steel HVM series High speed roll forming machineEPS sandwich panel machineSIN beam Automatic Welding Linegalvanized sheet slitter making machine/steel plate slitting machineDownspout/downpipe roll forming machine hot sellwall roof tile floor deck panel forming machine floor tile making automatic machineDouble Feeding C U Shape Metal Stud Channel rolling forming machineAdvanced Multi-Model Color Steel Roof Panel Roll Forming MachineAuto Steel Coil Holder/Hydraulic Uncoil With Coil Car 5 Tons