Downspout/downpipe roll forming machine hot sell

Basic Info

Model No.: Downpipe Machinery

Product Description

Product Description Main Features 1.machine adopt advanced technicall

2.high quality of the structure

3,one year warranty

4.more the 10 years experience

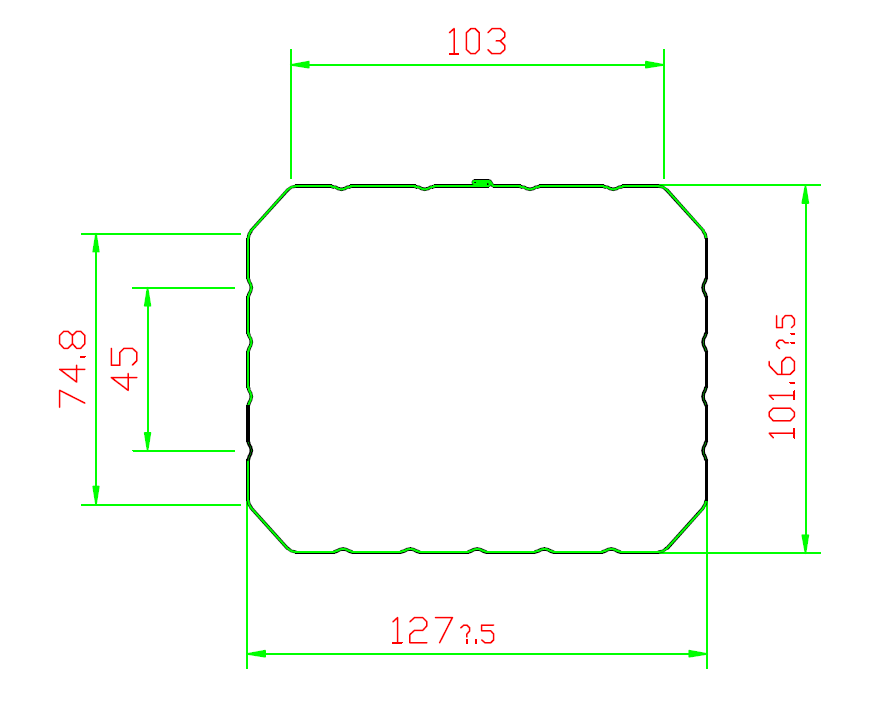

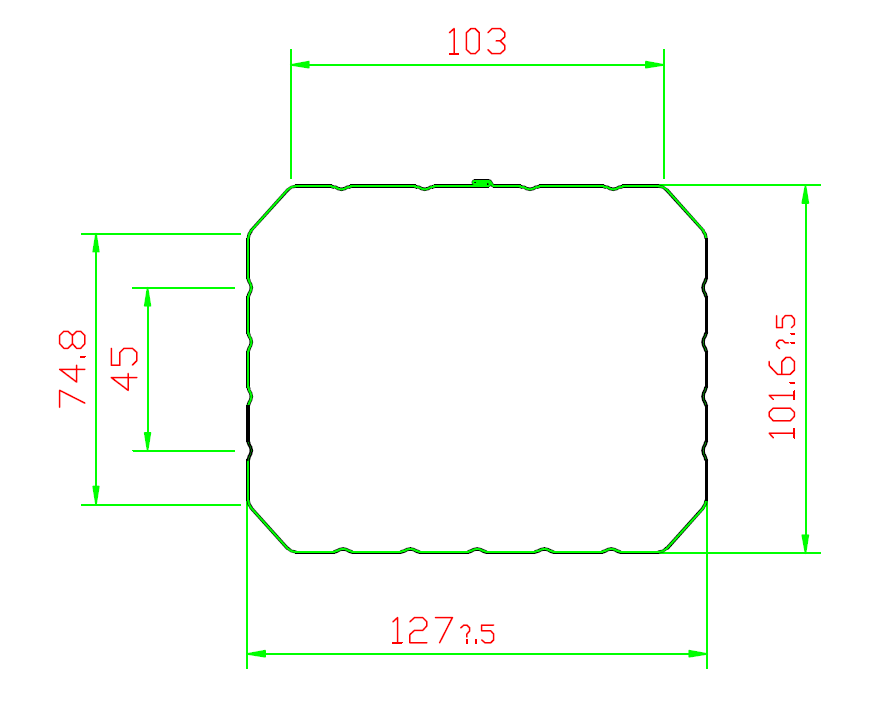

profile

profile

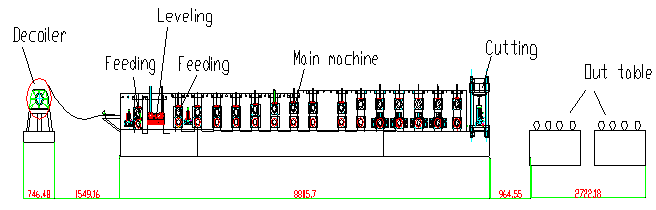

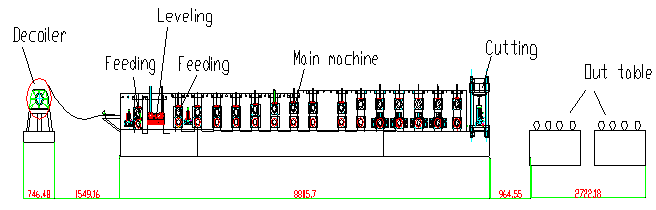

Equipment Flowsheet

Equipment Flowsheet  Detailed Technology

Detailed Technology

Packing & Delivery No paking, directly fix the machine to the container with belt and wood.

Our Service 1.1 year and life-long maintenance; 2.Installation and debugging:We will send professional engineer to make installation and debugging,buyer pay our engineer eachi one 50USD/day,and provide accommodation ,food and the round-trip ticket fee; 3.Installation Days:about 5-7 days

Our Service 1.1 year and life-long maintenance; 2.Installation and debugging:We will send professional engineer to make installation and debugging,buyer pay our engineer eachi one 50USD/day,and provide accommodation ,food and the round-trip ticket fee; 3.Installation Days:about 5-7 days

Our machine is definitely guarantee for 12 months. If there is any problem,we will send the technician to fix the problem ASAP!

Certifications Our Company Our main products include roll forming machines, guardrail roll forming machines, steel deck forming machines, door & window frame roll forming equipment, steel metal door making lines, guide rail rollforming machines, upright post roll formers, pipe and tube roll formers, purlin cold roll forming machines, T-bar forming machines, grape trellis roll forming machines, roof tile forming machines, steel metal panel roll forming machines, stud and track forming machines, cable tray roll forming machines, shelf rack making machines, gutter roll forming machines, roller shutter manufacturing lines, car bumper forming machines, car door forming machines, distribution cabinet making machines, channel roll forming machines and so on.

Our Company Our main products include roll forming machines, guardrail roll forming machines, steel deck forming machines, door & window frame roll forming equipment, steel metal door making lines, guide rail rollforming machines, upright post roll formers, pipe and tube roll formers, purlin cold roll forming machines, T-bar forming machines, grape trellis roll forming machines, roof tile forming machines, steel metal panel roll forming machines, stud and track forming machines, cable tray roll forming machines, shelf rack making machines, gutter roll forming machines, roller shutter manufacturing lines, car bumper forming machines, car door forming machines, distribution cabinet making machines, channel roll forming machines and so on.

Related Products

Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Contact us if you need more details on Water Pipe Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pipe Rolling Machine、Pipe Line Machin. If these products fail to match your need, please contact us and we would like to provide relevant information.

Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Contact us if you need more details on Water Pipe Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pipe Rolling Machine、Pipe Line Machin. If these products fail to match your need, please contact us and we would like to provide relevant information.

2.high quality of the structure

3,one year warranty

4.more the 10 years experience

profile

profile  Equipment Flowsheet

Equipment Flowsheet  Detailed Technology

Detailed Technology

Our Service 1.1 year and life-long maintenance; 2.Installation and debugging:We will send professional engineer to make installation and debugging,buyer pay our engineer eachi one 50USD/day,and provide accommodation ,food and the round-trip ticket fee; 3.Installation Days:about 5-7 days

Our Service 1.1 year and life-long maintenance; 2.Installation and debugging:We will send professional engineer to make installation and debugging,buyer pay our engineer eachi one 50USD/day,and provide accommodation ,food and the round-trip ticket fee; 3.Installation Days:about 5-7 days Our machine is definitely guarantee for 12 months. If there is any problem,we will send the technician to fix the problem ASAP!

Certifications

Our Company Our main products include roll forming machines, guardrail roll forming machines, steel deck forming machines, door & window frame roll forming equipment, steel metal door making lines, guide rail rollforming machines, upright post roll formers, pipe and tube roll formers, purlin cold roll forming machines, T-bar forming machines, grape trellis roll forming machines, roof tile forming machines, steel metal panel roll forming machines, stud and track forming machines, cable tray roll forming machines, shelf rack making machines, gutter roll forming machines, roller shutter manufacturing lines, car bumper forming machines, car door forming machines, distribution cabinet making machines, channel roll forming machines and so on.

Our Company Our main products include roll forming machines, guardrail roll forming machines, steel deck forming machines, door & window frame roll forming equipment, steel metal door making lines, guide rail rollforming machines, upright post roll formers, pipe and tube roll formers, purlin cold roll forming machines, T-bar forming machines, grape trellis roll forming machines, roof tile forming machines, steel metal panel roll forming machines, stud and track forming machines, cable tray roll forming machines, shelf rack making machines, gutter roll forming machines, roller shutter manufacturing lines, car bumper forming machines, car door forming machines, distribution cabinet making machines, channel roll forming machines and so on.Related Products

Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Contact us if you need more details on Water Pipe Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pipe Rolling Machine、Pipe Line Machin. If these products fail to match your need, please contact us and we would like to provide relevant information.

Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Contact us if you need more details on Water Pipe Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pipe Rolling Machine、Pipe Line Machin. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Down Pipe And Gutter

Premium Related Products

Other Products

Hot Products

EPS Sandwich Panel Machine (AF-S1000)C Purlin Roll Forming Machine (AF-80-300)H Beam Welding Lineguard rail forming machineroll forming equipmentDump truckCovering Machinecold steel HVM series High speed roll forming machineEPS sandwich panel machineSIN beam Automatic Welding Linegalvanized sheet slitter making machine/steel plate slitting machineDownspout/downpipe roll forming machine hot sellwall roof tile floor deck panel forming machine floor tile making automatic machineDouble Feeding C U Shape Metal Stud Channel rolling forming machineAdvanced Multi-Model Color Steel Roof Panel Roll Forming MachineAuto Steel Coil Holder/Hydraulic Uncoil With Coil Car 5 Tons