Self aligned Welding Rotator/Self opened Welding Rotator

| Unit Price: | 4000~5000 USD |

|---|---|

| Min. Order: | 1 Set/Sets |

| Packaging: | Seaworthy packing |

|---|---|

| Productivity: | 100 sets per month |

| Brand: | Zhouxiang |

| Transportation: | Ocean,Land |

| Place of Origin: | China |

| Supply Ability: | 100 sets per month |

| Certificate: | ISO9001, CCC, CE, TUV |

| HS Code: | 8468800000 |

| Port: | Shanghai,Ningbo,Nantong |

Basic Info

Model No.: GLHZ Self-alignment Welding Rotator

Click on the follow link to find out more information: https://www.beamweldingmachine.com/welding-rotator/

Company Info

- Company Name: Wuxi Zhouxiang Complete Set of Welding Equipment Co., Ltd.

- Representative: huizhong xu

- Product/Service: H Beam Welding Machine , H Beam Assembly Welding Straightening Machine , H beam Horizontal Productions Line , Box Column Productions Line , Automatic Assistant Welding Machine , Street Lamp Post Productions Line

- Capital (Million US $): 4700000

- Year Established: 1991

- Total Annual Sales Volume (Million US $): US$10 Million - US$50 Million

- Export Percentage: 41% - 50%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: 10

- No. of R&D Staff: 31 -40 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 50,000-100,000 square meters

- Factory Location: No. 68 Huairen Road, Donggang Town, Xishan District, Wuxi, Jiangsu, China

- Contact Person: Ms. Katherine

- Tel: +86-0510-88794887

Email to this supplier

Premium Related Products

Other Products

Hot Products

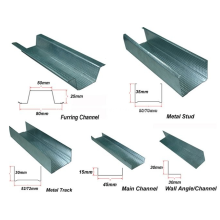

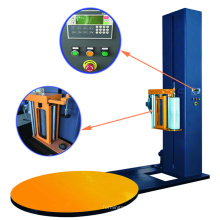

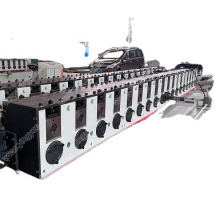

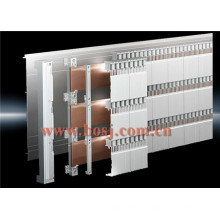

EPS Sandwich Panel Machine (AF-S1000)C Purlin Roll Forming Machine (AF-80-300)H Beam Welding Lineguard rail forming machineroll forming equipmentDump truckCovering Machinecold steel HVM series High speed roll forming machineEPS sandwich panel machineSIN beam Automatic Welding Linegalvanized sheet slitter making machine/steel plate slitting machineDownspout/downpipe roll forming machine hot sellwall roof tile floor deck panel forming machine floor tile making automatic machineDouble Feeding C U Shape Metal Stud Channel rolling forming machineAdvanced Multi-Model Color Steel Roof Panel Roll Forming MachineAuto Steel Coil Holder/Hydraulic Uncoil With Coil Car 5 Tons