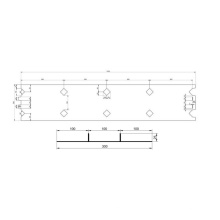

1. Profile drawing: Finalized in drawing which is approved by both parties 2. Main parameters 2.1 Suitable material: Ø Raw material: Galvanized coil sheet Ø Yield stress: ≤300Mpa Ø Thickness: C-Track 1.25 mm/ C-Track Element 1.25mm 2.2 Technical parameters Ø Air supply: >0.5Mpa Ø Speed: ~10m/min(not include shearing and punching ) Ø Power supply: 380V±10%;50HZ 3. Working flow(as per the layout drawing) Decoilling→Levelling→Roll forming→Punching→Shearing→ Run-out table 4. Machine components:

No. | Name | Model | Unit | QTY | Remark |

1 | Decoiller | Hydraulic | set | 1 | |

2 | Straightening | Seven rollers leveling | set | 1 | |

3 | Lubricating device | wool felt lubrication | set | 1 | |

4 | Roll forming unit | Column wall | set | 1 | |

5 | Punching | Fast punching | set | 1 | |

6 | Shearing | Hydraulic | set | 1 | |

7 | Run-out table | Simple table | set | 1 | |

8 | Hydraulic system | Professional | set | 2 | |

9 | Electrical system | Whole line control | set | 1 | |

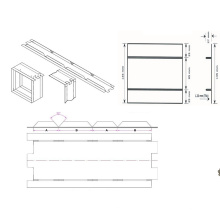

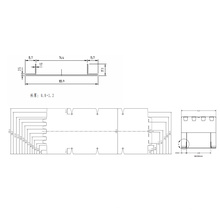

1. Machine components and structure introduction 5.1,Decoiler Ø Driven by electrical motor Ø Hydraulic expanding with a connecting rod mechanism Ø Mounted with pneumatic braking device Ø Mounted with eight coil material link stopper. When loading the coil, fix two material link stopper at each side of coil sheet to prevent it from loosening. 5.2,Leveler Ø It consists of 7 leveling rollers, two pinch rollers and five leveling rollers. Ø Adopt motor driving. Ø The leveling rollers can be adjusted to be up and down through one screw rod and pinch rollers through one pneumatic cylinder 5.3,lubricating device Ø This an independent device which is installed before entrance of roll forming to prevent zinc coating from scratch. 5.4,Roll forming unit Ø Adopt independent column wall structure and independent gear box transmission design. Ø Adopt quick cassette shifting design when to change profiles, this design can’t be mounted with safety guard due to the cassette replacement. Ø Roll forming stations: 18+18 stands(depend on final design, leave space on the machine base for extra four stands of rollers) Ø Shaft diameter: Ø60mm(depend on final design) Ø The lower rollers are fixed while the upper ones can be adjusted through screw rod to adjust the gap between upper and lower rollers. Ø Side nuts of roll forming stands wall rotate with counterclockwise (lower shaft)and clockwise (upper shaft); Ø Roll forming stands wall material: QT470. Ø Main shaft material: 40Cr ,hardness is HRC45 after quenching treatment Ø Roll forming unit motor power: about 15KW Rollers: Ø Rollers material: Cr12 hardness is HRC 58-62 with quenching treatment and polishing treatment Ø All rollers is marked at the side and the spacers is marked on the surface for future replacement.

Contact us if you need more details on Cable Tray Sizes. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cable Tray Sizes、Cable Tray Sizes. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Roll Forming Machinery > Other Forming Machinery

1. Profile drawing: Finalized in drawing which is approved by both parties 2. Main parameters 2.1 Suitable material: Ø Raw material: Galvanized coil sheet Ø Yield stress: ≤300Mpa Ø Thickness: C-Track 1.25 mm/ C-Track Element 1.25mm 2.2 Technical parameters Ø Air supply: >0.5Mpa Ø Speed: ~10m/min(not include shearing and punching ) Ø Power supply: 380V±10%;50HZ 3. Working flow(as per the layout drawing) Decoilling→Levelling→Roll forming→Punching→Shearing→ Run-out table 4. Machine components:

1. Profile drawing: Finalized in drawing which is approved by both parties 2. Main parameters 2.1 Suitable material: Ø Raw material: Galvanized coil sheet Ø Yield stress: ≤300Mpa Ø Thickness: C-Track 1.25 mm/ C-Track Element 1.25mm 2.2 Technical parameters Ø Air supply: >0.5Mpa Ø Speed: ~10m/min(not include shearing and punching ) Ø Power supply: 380V±10%;50HZ 3. Working flow(as per the layout drawing) Decoilling→Levelling→Roll forming→Punching→Shearing→ Run-out table 4. Machine components: