1025mm/1090mm Double Layer Roll Forming Machine

Basic Info

Model No.: YX25-207-828

Product Description

Our Company Jiangyin Bangnuo Machinery Co., Ltd. is a professional manufacturer dedicated Color light steel construction, C, Z steel equipment and rolling, bending molding equipment enterprises, with the design and manufacture of various types of steel sheet thickness roll forming production line strength. Pressed tile color steel plate and C, Z purlin products are widely used in various types of large and small industrial plants, warehouses, residential and high-rise buildings. With economic development, building light steel building applications on the growing popularity of the increasing demand for production equipment, production equipment automation requirements are also increasing, company investment, research and development of various types of color steel pressure plate (W) production line and C, Z-beam (purlin) production equipment, the use of simple, improve productivity, reduce production costs. Various existing models of steel pressure plate (W) C, Z-beam (purlin) automatic control production line are at the leading position at home and abroad, with a compact structure, reasonable design, constantly updated progress and much Strut Builders and products the favor and praise.

Company specializing in the production of Dagong machines, floor plate machine, guardrail plate machine, corrugated tile machine, shearing machine, sub-board machine, highway guardrail, tile machine equipment, automatic tile press, iron Piva machine, iron tile machine, all automatic C-shaped steel machine, glazed tile machine.

Product Details

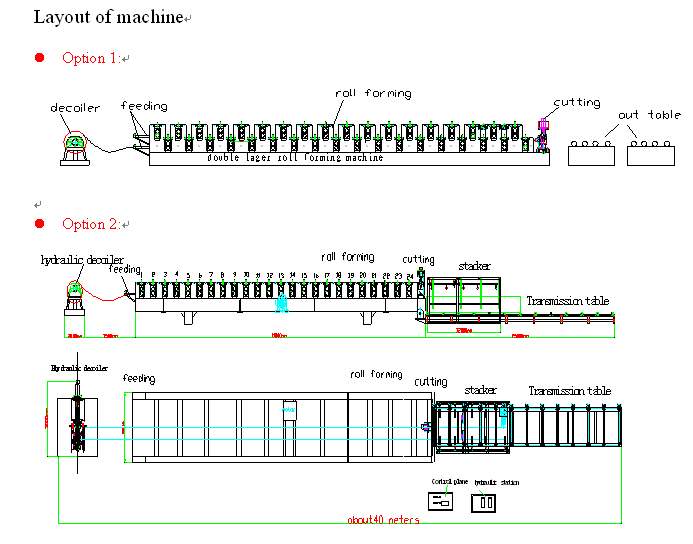

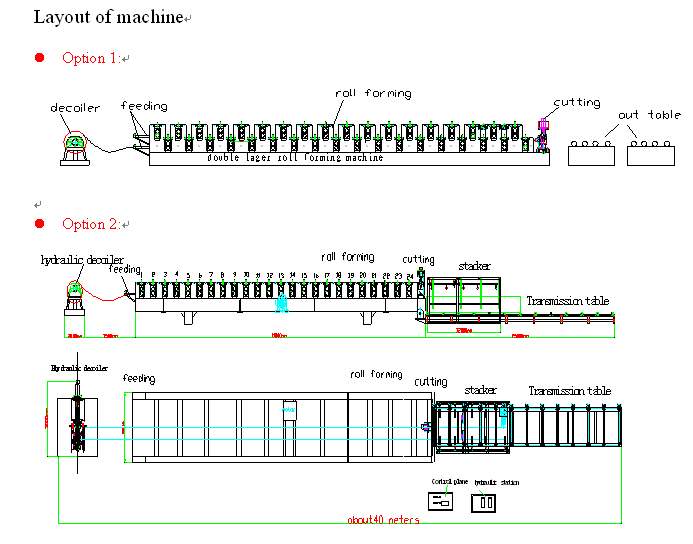

The production flow of equipment Option 1:

The production flow of equipment Option 1:

Manual de-coiler→ Feeding→roll forming→post cutting →Manual out table

Option 2:

Hydraulic de-coiler( with coil car )→ Feeding→roll forming→post cutting →auto stacker

Machine Composition De-coiler Dimensions : 1700mm*1000mm*800mm

De-coiler Dimensions : 1700mm*1000mm*800mm

Width of feeding : 1250mm

Capability : 5 Ton

Inter diameter : 480-570mm

Maximal out diameter : 1500mm

Mode of expand &fight : inner expand &fight by manual

Way of feeding : manual

Color : blue

Feeding

Feeding

Adjustable center of the forming rollers and of sufficient length to prevent lateral movement of the strip on its entry to flattener.

Feeding type: adjustable

Feeding width range: about 1300mm

Entrance and guide roller: diameter is ¢76mm, material is SAE1045, HRC48-52° surface with chrome

Quantity: 1

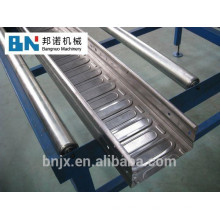

3: Receiving table

Main structure (layout) for the auto stacker

Main structure (layout) for the auto stacker

Our Service Pre-sales service

Our Service Pre-sales service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-sales service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

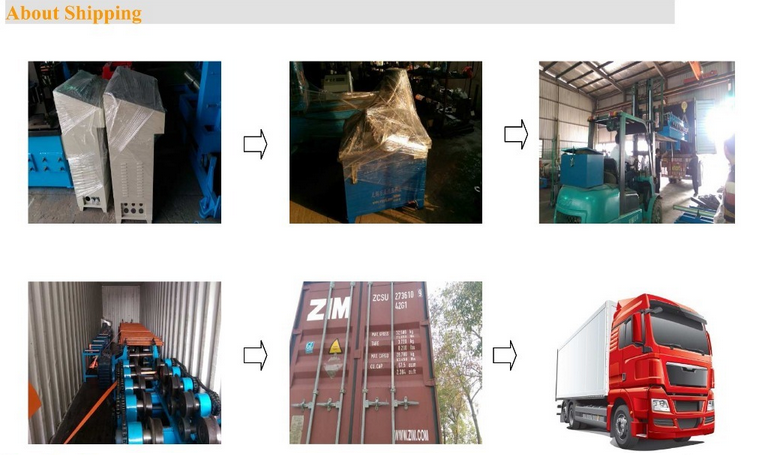

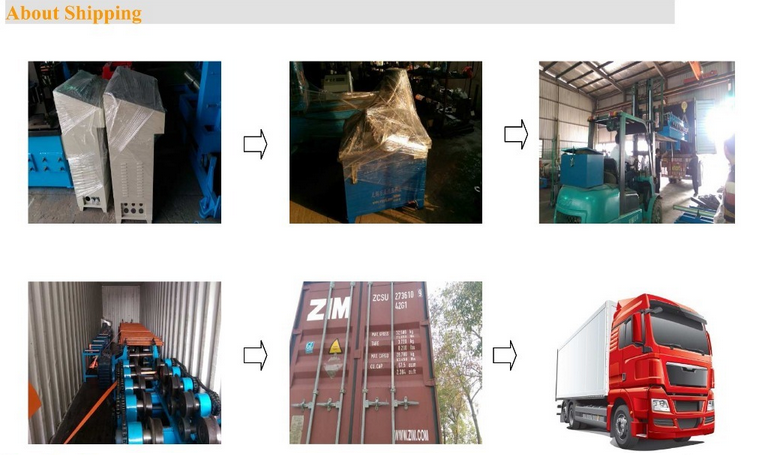

Certifications Packing & Delivery

Packing & Delivery  Related Products

Related Products

Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Contact us if you need more details on Galvanized Roof. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wall Pane、Double Layer Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Contact us if you need more details on Galvanized Roof. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wall Pane、Double Layer Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Company specializing in the production of Dagong machines, floor plate machine, guardrail plate machine, corrugated tile machine, shearing machine, sub-board machine, highway guardrail, tile machine equipment, automatic tile press, iron Piva machine, iron tile machine, all automatic C-shaped steel machine, glazed tile machine.

Product Details

The production flow of equipment Option 1:

The production flow of equipment Option 1:Manual de-coiler→ Feeding→roll forming→post cutting →Manual out table

Option 2:

Hydraulic de-coiler( with coil car )→ Feeding→roll forming→post cutting →auto stacker

Machine Composition

De-coiler Dimensions : 1700mm*1000mm*800mm

De-coiler Dimensions : 1700mm*1000mm*800mmWidth of feeding : 1250mm

Capability : 5 Ton

Inter diameter : 480-570mm

Maximal out diameter : 1500mm

Mode of expand &fight : inner expand &fight by manual

Way of feeding : manual

Color : blue

Feeding

FeedingAdjustable center of the forming rollers and of sufficient length to prevent lateral movement of the strip on its entry to flattener.

Feeding type: adjustable

Feeding width range: about 1300mm

Entrance and guide roller: diameter is ¢76mm, material is SAE1045, HRC48-52° surface with chrome

Quantity: 1

Main structure (layout) for the auto stacker

Main structure (layout) for the auto stacker

Our Service Pre-sales service

Our Service Pre-sales service* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-sales service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Certifications

Packing & Delivery

Packing & Delivery  Related Products

Related Products

Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Contact us if you need more details on Galvanized Roof. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wall Pane、Double Layer Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Products Name with link 91.8% Response Rate Contact us if you need more details on Galvanized Roof. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wall Pane、Double Layer Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Metal Deck Roll Forming Machine

Premium Related Products

Other Products

Hot Products

EPS Sandwich Panel Machine (AF-S1000)C Purlin Roll Forming Machine (AF-80-300)H Beam Welding Lineguard rail forming machineroll forming equipmentDump truckCovering Machinecold steel HVM series High speed roll forming machineEPS sandwich panel machineSIN beam Automatic Welding Linegalvanized sheet slitter making machine/steel plate slitting machineDownspout/downpipe roll forming machine hot sellwall roof tile floor deck panel forming machine floor tile making automatic machineDouble Feeding C U Shape Metal Stud Channel rolling forming machineAdvanced Multi-Model Color Steel Roof Panel Roll Forming MachineAuto Steel Coil Holder/Hydraulic Uncoil With Coil Car 5 Tons